Making nålbinding needles has become a new hobby My very first needles i made were from an ice cream stick.

The stick was made of beech wood, flat,not too thick and i was able to make my first needles with it. The needles were not really durable and i started using other material, viz. bamboo. Bamboo is very strong, flexible and you can also sand it very smooth.

In the foto above the bamboo needle is 12 cm long, 5,5 mm wide and flat with a blunt tip. I was still looking for the right proportions, the ‘blunt’ tip was perfect because you don’t pierce your thread. The bamboo needles i made next were 5 cm to 14 cm long and 1cm to 5 mm. wide and smoothed with 1000 grit sandpaper. After the bamboo needles i made needles from : Antler. Cowhorn. Taksis. Hawthorn. Santos palisander. Bloodwood, kokobolo and teak wood.

These materials are precious and very beautiful and you can polish the needles very smooth. The foreign types of wood are also not always available. Bamboo, on the other hand, is often for sale in garden centres. You have bamboo (thin wall) and the tonkin, which has little sap wood.

Here you can see how i make my NEW OVAL NEEDLES. The needles are NOT flat but……….OVAL, so they slide even easier between your fingers 🙂

The bamboo is first sawn to manageable lenght with a jigsaw.

The dirty bamboo is scraped clean with a scraping iron.

Close up picture.

When the bamboo is clean i will cut it to lenght (9 cm) with my band saw.

The next operation is splitting the bamboo.

With this splitting, the Bamboo is divided into 4 strips.

After this, a hole of 3,5 mm. drilled into the bamboo strips.

After drilling, the edge of the hole is cleared.

The edge of the hole is now smooth.

The sapwood is cut from the strip.

After this, the bamboo strip is cut into the shape of the needle with my knife.

This is the rough shape.

The oval shape is sanded with 80 grit coarse sandpaper.

After this i will sand with grit 400.

Then with grit 600.

Then with grit 1000 the needle is already fairly smooth.

And then with 1500 grit the needle is smooth.

It should now shine even smoother and more beautiful, so grit 2000.

And then with grit 3000 the needle is very smooth end the bamboo shines.

With 3M 6000 pad the needle becomes super smooth and the needle shines even better.

And………..then there is also 3M 8000 pad and the needle becomes Super SMOOTH and it is Super SHINY 🙂

Cose up picture: Oval nålbinding needle

The New needles are NOT flat but Oval, so that they slide even more easily between your fingers. I treat my needles with grape seed oil. Research has shown that almost 1 % of the population is allergic. I deliberately did not use beeswax because of vegan motives.

After 45 minutes the needle is ready 🙂 Have fun with making nålbinding needles and choose the materials what you prefers.

Dalbergia Melanoxylon.

The wood species Dalbergia melanoxylon is the name of a small slow-growing tree from Africa.

This beautiful rare and expensive wood also has other names: Grenadille, African blackwood, M’pingo. In Africa it is used to make beautiful statues and in Europe it is used to make musical instruments, including the clarinet and oboes. At a 2nd Hans market I came across a broken statue that turned out to be made of Grenadille. I started upcycling this statue, a modern word for giving old things a new life.

Making my new Oval needle binding takes a bit longer than a Bamboo needle, 1 hour and fifteen minutes.

The wood looks like ebony, but it is not. Due to its high weight and the associated hardness, the African Grenadilla is difficult to work with. The wood can be polished smoothly. It has become a very beautiful exclusive Needle.

Photinia fraseri.

The shrub/tree Shiny medlar, botanical name Photinia fraseri grows in our garden. This species also occurs in Southeast Asia and the Himalayas.

Two years ago I pruned the shrub from this hard, tough wood and i made an oval needle. The Needle is made according to the tutorial above.

It is very nice wood, and I was able to polish it very smooth.

AMP-hout.

At the 2de Hans market I came across a bottle opener with a large wooden handle. I don’t know yet what this beautiful wood is called, the letters AMP were on the opener. For now I’ll call this wood AMP wood.

From this handle I saw 11 strips of this beautiful wood with my bandsaw machine. This rather hard and tough wood was easy to work with.

It is very nice wood, and I was able to polish it very smooth. I now know what kind of wood it is: Palisander wood. The wood vademecum book is a great book for looking up wood, better than Google.

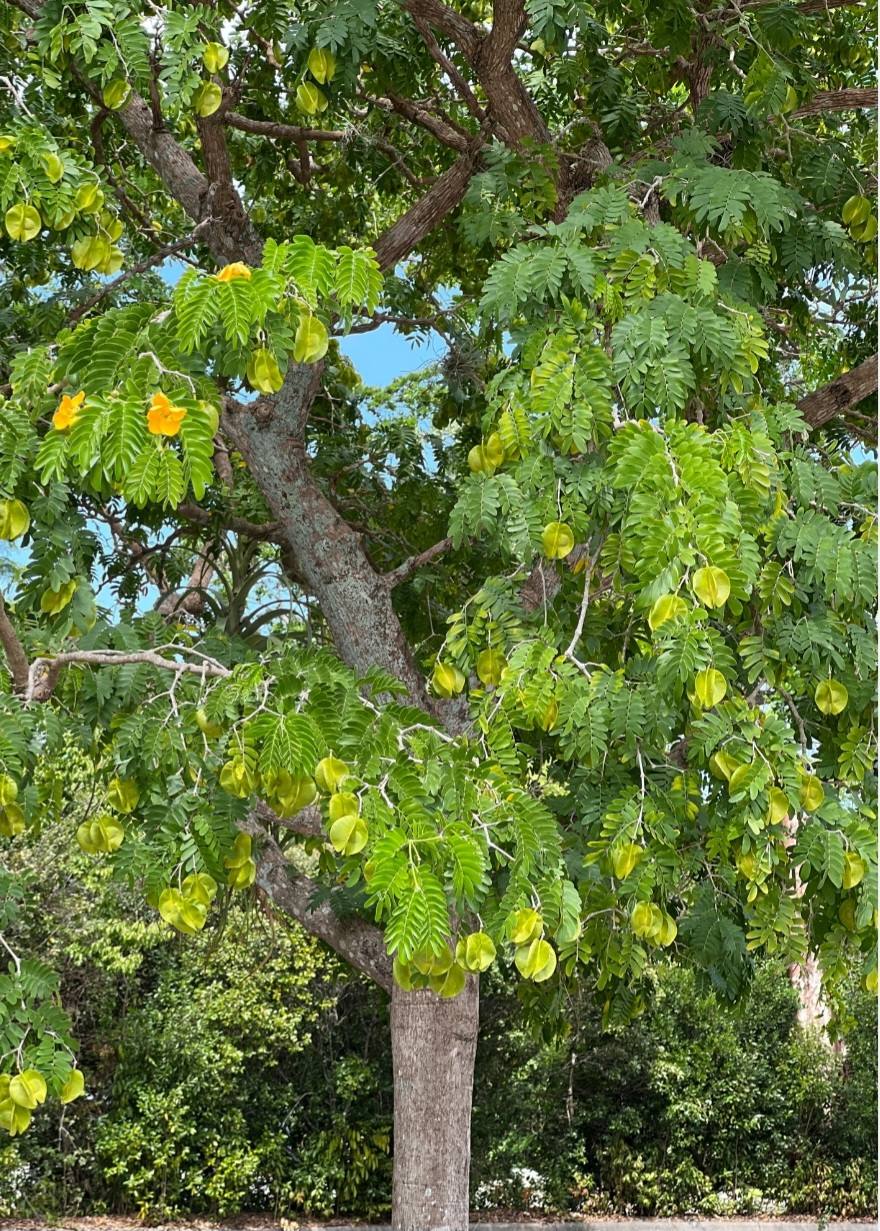

Taxus baccata.

This is a photo of the yew tree/shrub in our front garden, the tree grows slowly and can live up to 700 years. The wood of the yew is: flexible, tough, and very hard and the wood has a beautiful pattern. Three years ago I received wood from my brother-in-law, and I now make the Oval needles from it 🙂

Yew wood can be polished beautifully and with grape seed oil the grain appears very nicely and the wood is also nourished and protected.

Crataegus monogyna.

The hawthorn tree/shrub can grow up to 10 meters. wood of the hawthorn is hard and strong. The trees date back 5,000 years before our era. The thorns of the tree are very sharp and hurt very much if you prick yourself. This beautiful wood is perfect for making needles.

I can also polish this hard wood nicely and I have treated it with grapeseed oil.

Discovering and searching for new types of wood is a new hobby.

When I was in a second hans shop I noticed a pair of walking sticks. This is heavy and hard wood and also nice and smooth. The idea was to make nice wood for needles. In my new book I can see what kind of wood this is.

Jatoba tree.

The orange-colored wood is Jatoba hard wood and grows in tropical Central and South America.

Pok tree.

The yellow/brown heavy wood appears to be Pok wood, it is hard and very smooth and it grows in Columbia and Venezuela.

On the foto the name Vera pok wood is wrong it has to be Pok wood.